Language

MOIRA CRS steel is crafted with a balanced mixture of three main chemical elements i.e Copper, Chrome, and Nickel which helps in providing an added strength to our steel and giving your construction a strong structure and longer life. At Moira Sariya we always Strive to Produce the best Quality Production & we are proudly the only Indian company that produces 100% CRS (Corrosion Resistance Steel) Steel.

Steel corroding in concrete might cause cracking or spalling of the concrete which reduces the life of the structure and also brings in added cost. The steel generally corrodes in existence of chloride ions; however, Moira TMT Bars are casted with a thermo-mechanical treatment making them highly rust and corrosion resistant. Because of this property, they are better suited for use especially in areas with higher humidity or coastal states.

Addition of copper, nickel, and chrome to the raw material providing Moira TMT bars higher corrosion resistance against ordinary bars made by sponge iron-based plants.

The composite uniform microstructure of Moira TMT bars gives it superior corrosion resistant properties when concrete embedded.

Moira TMT bars are Quality checked with extreme rusting conditions through salt corrosion testing methods thereby ensuring standards.

Longer Life Because of the excellent ability to resist Corrosion.

Higher ductility and bending capacity.

Easily Wieldable bars to avoid errors in wielding.

Reliable under extreme conditions, such as ground water, salty water, and airborne acid particles.

Higher yield strength and hence can be used in seismic activity zones.

Usable in construction along sewage drains and sewage treatment plants against the steel bar which has more chances to get damaged due to salts or acids or bases in sewage.

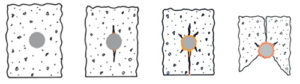

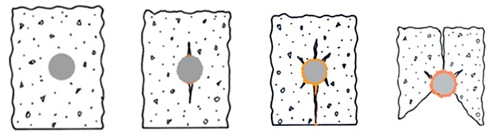

The three stages of corrosion for concrete embedded steel are:

Incubation

Initiation

Propagation

Below mentioned is a diagrammatic representation of the different stages:

The rate of corrosion at later stage (propagation stage) is significantly accelerated once the concrete cracks due to rust formation. This implies a very quick de-structuring of the construction and calls for repair/rework.

Uncoated steel rebar corrosion begins with rust on the surface of the bar thereby causing cracks near the steel and concrete interface. This further expands. With time, the corrosion products build up and further deteriorate the interface which results in more extensive cracking. This finally results in concrete eventually breaking away and leaving the bar thereby causing spalling.