Language

Moira TMT bars are amongst few of the superior bars available today.

Our Fe-500 D grade bars have an ability to yield a minimum stress of 500 N/mm2 and display a high percentage of elongation. This is explicit from the ‘D’ in Fe-500 D which denotes ductility. This also makes Moira 500 D TMT bars ideal for seismic resistance and totally free of mechanical fatigue.

D variety of Moira TMT bars have been introduced by BIS in their latest armament in 2008.

This category of TMT Bars demonstrates a higher tensile strength and ductility on and above normal grade TMT bars. 500 D variety TMT bars are manufactured with an enhanced process which requires next level finesse. They are made by a special category of billets under a critically controlled thermal treatment during their manufacturing.

Both Moira Fe 500 and Fe 500 D TMT bars are superior sariya grades and ideal for different types of construction projects. To compare them, Fe 500 D TMT bars have a greater ductile strength than the Fe 500 TMT bars. However Tensile strength of steel is same for both the varieties.

| Elements (Max. %) - Fe 500 D | |

| Carbon % | 0.25 |

| Sulphur % | 0.040 |

| Phophorus % | 0.040 |

| Sulphur and Phorphorus % | 0.075 |

| Yield Strength (N/mm2) | 500 |

| Ultimate Tensile Strength, Min (n/mm2) | 565 |

| Elongation Min (%) | 16 |

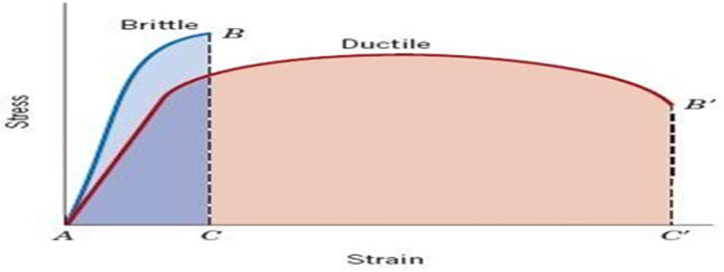

When a piece of ductile material is pulled, it deforms and changes its shape to adapt to the stress before rupture (breaking apart). By doing so, our bars absorb energy, represented by the area under the curve AB’.

The opposite of ductile is brittle. A brittle material absorbs very little energy during stress, (the area under the curve AB) and has usually very less plasticity.