It has been found that the most differentiating factor to survive earthquakes with least damage is the use of high-quality TMT bars which should stick to minimum requirements defined in IS 1786-2008.

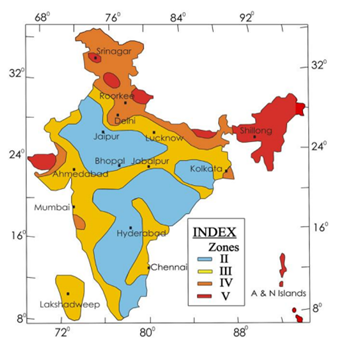

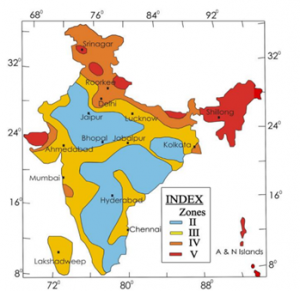

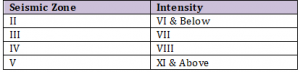

Based on scientific inputs for seismicity, earthquakes in the past and tectonic setup of the region, Bureau of Indian Standards (BIS) defined four seismic zones which mapping intensity levels of earthquakes:

Cities / towns in India majorly fall under Seismic Zones III, IV and V; and hence an increased focus on earthquake resistant construction in the country is need of the hour.

- Zone V: The areas under zone V are most vulnerable to earthquakes; Entire northeastern India, parts of Jammu and Kashmir, Himachal Pradesh, Uttaranchal, Rann of Kutch in Gujarat, part of North Bihar and Andaman & Nicobar Islands.

- Zone IV: Remaining parts of Jammu and Kashmir and Himachal Pradesh, National Capital Territory (NCT) of Delhi, Sikkim, Northern Parts of Uttar Pradesh, Bihar and West Bengal, parts of Gujarat and portions of Maharashtra near west coast and Rajasthan.

- Zone III: Kerala, Goa, Lakshadweep islands, remaining parts of Uttar Pradesh, Gujarat and West Bengal, Parts of Punjab, Rajasthan, Madhya Pradesh, Bihar, Jharkhand, Chhattisgarh, Maharashtra, Orissa, Andhra Pradesh, Tamil Nadu and Karnataka.

- Zones II: Other parts of India.

Based out of the Industrial area in Pithampur, alias the manufacturing hub of Central India, Moira has an annual capacity of producing 4 lac tons of TMT Bars. Moira TMT bars brings in the best quality TMT bars specially designed to withstand seismic stress.

Usage of safe construction strategies / building materials can save many lives from disastrous natural calamities like an earthquake. The ability of a structure to stand erect and shock proof is directly proportional to kind of TMT Bars used for laying its foundation. The cement used in the building also plays critical role for providing strength to the building. However the major strength comes from TMT Bars which is the chief construction element and bears the entire weight of the building.

The high energy which gets generated on a structure during an earthquake demands a highly ductile material that can absorb the immense force without breaking, which a brittle material does not support. When technology was not so developed, manufacturing such TMT bars for regions of Central India has been a challenge. However Moira takes pride in making such TMT bars made available in Indore, Dhar, Pithampur, Gwalior, Ratlam etc.(List all regions of central India where Moira supplies) at an affordable range making safety a priority.

Our TMT bars are added with manganese to give a higher ductility unlike the ordinary bars which helps the bar to elongate furthermore and withstand high stress. Moira TMT bars have undergone various studies to establish their superiority and strength in context to seismic resistance. The experimentation of continued reversed loading with large deformations which resulted in same energy dissipation by Moira Bars for each cycle in all the studies justifies the uniformly maintained ductility and the fact that our TMT bars are the best pick for making a structure stand tall and strong in all parts of Central India.

Moira TMT bars; encompassing various properties of earthquake resistance, thermal resistance, corrosion resistance, high ductility, bendability and elongation, are without say the best bet for all regions like (Cities of supply) Madhya Pradesh, (Cities of supply) Uttar Pradesh or (Cities of supply) Chhattisgarh.

Mandrel bend test:

Under Mandrel bend test, bars are tested on a bending machine to ensure that no cracks appear. The more difficult it is to bend the bar, the better it is thus, the ideal TMT bar does not develop cracks even when it is bent at an angle equal or higher than 90 degrees.

Our TMT bars undergo this testing, post-production to ensure the quality required to be a seismic resistant TMT bar.