The common belief is that cement or concrete provides the strength in a building. This is only partly true – a large part of the strength of a structure comes from the steel structure that holds the concrete together. So naturally, if this steel frame corrodes the entire structure is at risk.

This is why corrosion resistant TMT or Thermo Mechanically Treated steel bars have become the gold standard for construction – especially in humid or coastal areas where weather conditions lead to a high degree of corrosion.

Why use TMT bars for construction in corrosion-prone areas?

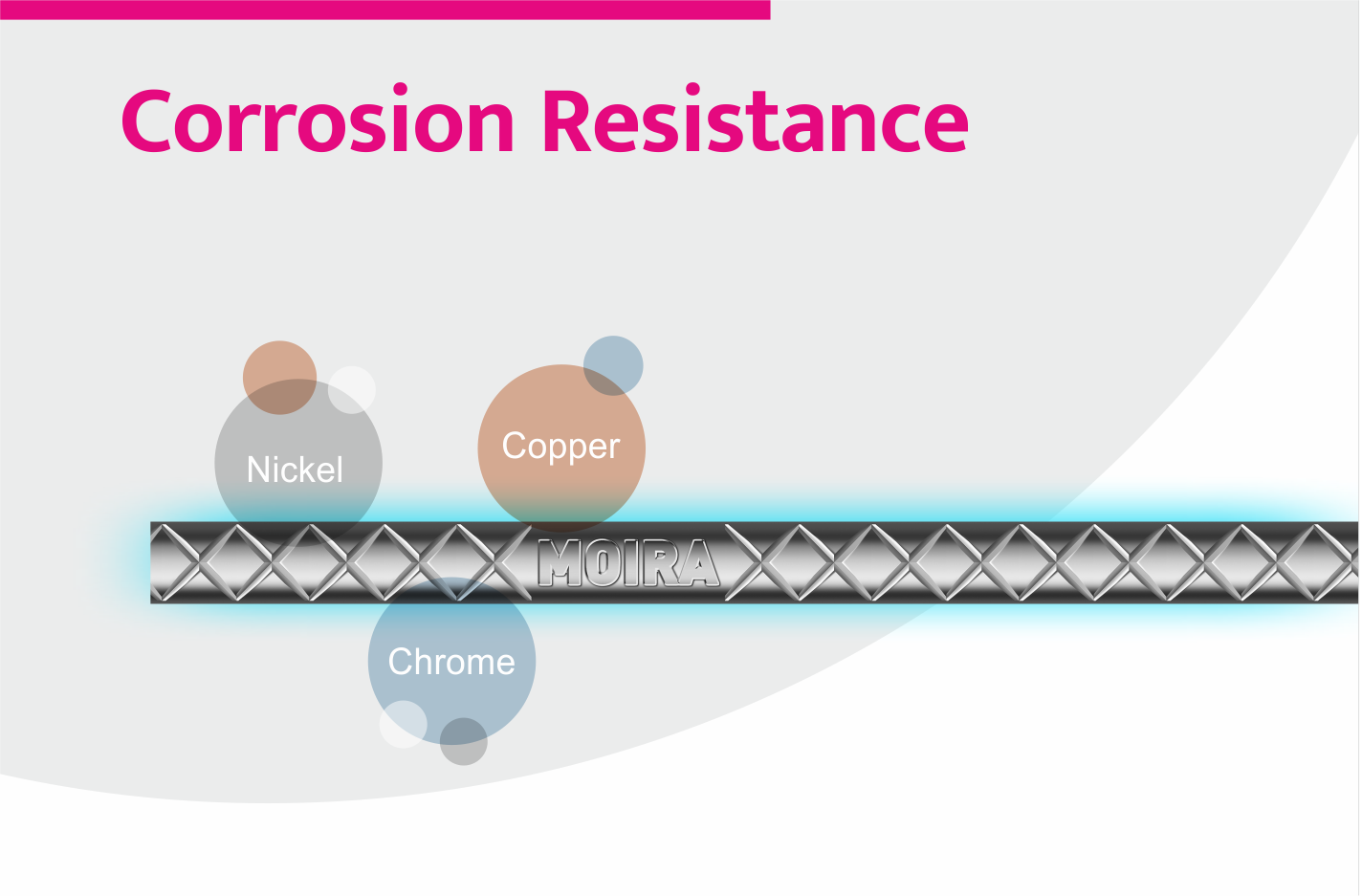

Because of its manufacturing process, which casts TMT bars with a thermo-mechanical treatment, these bars have enhanced rust and corrosion resistance. Manufacturers like MoiyraSariya also add copper, nickel, and chrome to the raw material providing Moira TMT bars even higher level of corrosion resistance.

This corrosion-resistant feature of TMT bars makes them extremely suitable for RCC structures in coastal areas or regions with high humidity.

Here are 5 Reasons why corrosion resistant TMT bars should be your choice of steel for your building

- Longevity of your structure

If you are building for the long term (and who doesn’t?), then it is best to use enhanced corrosion-resistant steel bars, because even if you don’t reside in a coastal or humid region, regular exposure to the weather will lead to some amount of damage to steel parts.

- Geographical Area

If you live in the coastal region of the country or the more moisture-laden northeast, then without doubt corrosion resistant TMT should be your default choice of steel for any type of building. This choice extends to earthquake-prone areas too, as even minimal corrosion can lead to collapse during a seismic event.

- Cost benefits

In the long run, it is so much more affordable to opt for TMT steel bars, because fixing corrosion-related damage will not only cost you more in maintenance and repairs but will also reduce the life of your building.

- More strength and ductility

TMT bars are proven to be more robust and flexible than other steel bars such as TOR steel. As there is no twisting involved in its production, it has no residual stress and is hence more corrosion resistant.

Its two-step cooling process gives TMT bars higher bendability, which makes it easier to work with on-site and gives it the flexibility to withstand seismic events.

- Peace of mind

Finally, knowing that you have used the best material for your building will give you long term peace of mind. You will rest easy knowing you have constructed a sturdy building that will stand the test of time and nature.

When it comes to construction, building for the long term is always the most cost-effective thing to do. Do not be swayed by the affordability of some steel bars you might find in the market – deal with a trusted vendor or go directly to the manufacturers like Moriya Saria to find the best quality corrosion resistant TMT bar for your structure.