TMT or Thermo-Mechanically Treated bars are the backbone of the modern construction industry – from simple homes to skyscrapers to bridges and underwater structures – no matter what is being constructed, dig a little, and you are bound to find TMT bars inside every concrete structure.

The reason TMT bars have found such wide acceptance across the entire spectrum of construction is because it offers high tensile strength and ductility. The manufacturing process, which cools molten steel rapidly as soon as it is rolled, gives the TMT bars its characteristic hard outer shells and soft inner core. The combination makes it strong, supple, and rustproof.

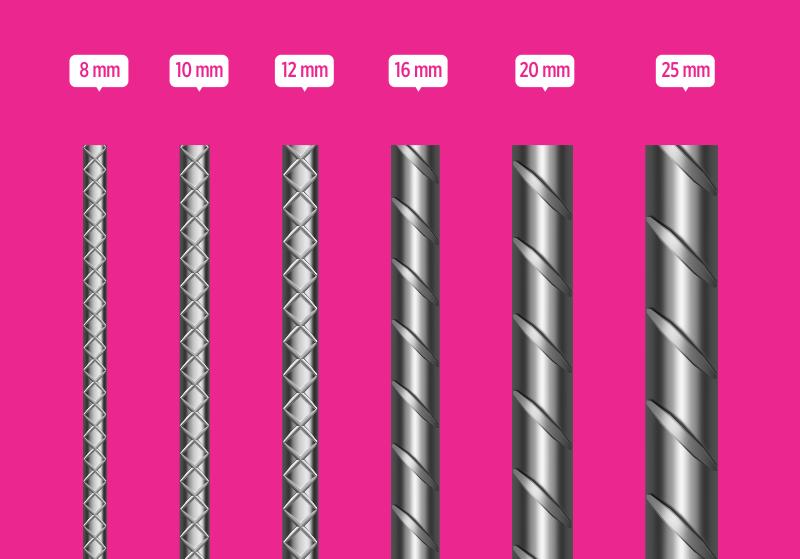

TMT bars come in a variety of grades (each grade comes in several sizes as well), and while the manufacturing process remains the same, each type has some unique characteristics that make it better suited for specific purposes.

TMT bars are given their grades according to their ductility and strength. The higher the grade, the stronger the bar! TMT steel bars come in 4 common grades – Fe 415, Fe 500, Fe 550 and Fe 600.

Here is an overview of the 2 most widely used grades –

- Fe 500 –

These steel bars can yield minimum stress of 500 N/mm2. So while these are also very bendable, they are structurally much stronger than Fe 415 and therefore recommended for the soil in Central India.

TMT bars also come in a sub-grade Fe-500 D, which possesses a high percentage of elongation, giving them extra strength and enhanced resistance to dynamic loading without compromising in ductility.

Fe 500 and Fe 500 D TMT bars are perfect for RCC construction of buildings, bridges, and similar structures.

- Fe 550 –

These are similar to Fe-500 except that they yield minimum stress of 550 N/mm2, making them even stronger. Fe-550 D, a variant, combines higher weldability and better ductility with the strength inherent to this grade.

Fe-500 is perfect for construction projects in marine, coastal, or underground environments. Fe-550 D is vibration and earthquake resistant and is mostly used for the construction of long-span structures like high-rise buildings, dams, bridges, etc.

TMT bars are the gold standard for RCC construction the world over and rightly so! The benefits the TMT manufacturing process adds to the steel makes it stronger, more flexible, corrosion-resistant, and more cost-effective. However, it always makes sense to keep an eye on quality and only source best quality TMT bars from a well-known manufacturer such as Moira Sariya.

As one of India’s leading manufacturers and suppliers high-quality TMT bars, we have been in the business for over 30 years. Our advanced, fully-integrated process ensures high strength, top quality, and long-lasting TMT bars for all types of construction. Fe 500, Fe 500 D, Fe 550 and Fe 550 D are manufactured at our facilities and come in a variety of thickness to suit a diverse number of construction prerequisites.

At Moira Sariya, we promise solid strength for lasting construction.