Thermo Mechanically Treated Bars (TMT bars) are manufactured by treating them thermally through quenching, heating and finally compressing to form bars.

Quenching refers to a heat treatment in a quenching box where rebars are rapidly cooled using a special water spray system. This hardens the surface of TMT bar while the core still remains hot and soft. After quenching of the bar, self-tempering happens during which the heated core of the bar supplies heat to outer martensitic surface making tempered martensite. Post tempering, atmospheric cooling is done on cooling beds to get the ductile ferrite-pearlite structure of the core. Moira TMT bars are manufactured using the latest German “CRS” technology. This technology involves exposing bars to temperature as high as 1100 degree Celsius, then passing through rolling mills and finally through high-pressure water which makes these bars cool outside and still heated at core inside on account of thermal exchange. This provides Moira TMT bar the characteristic property of having an inner soft core and a tougher outer core.

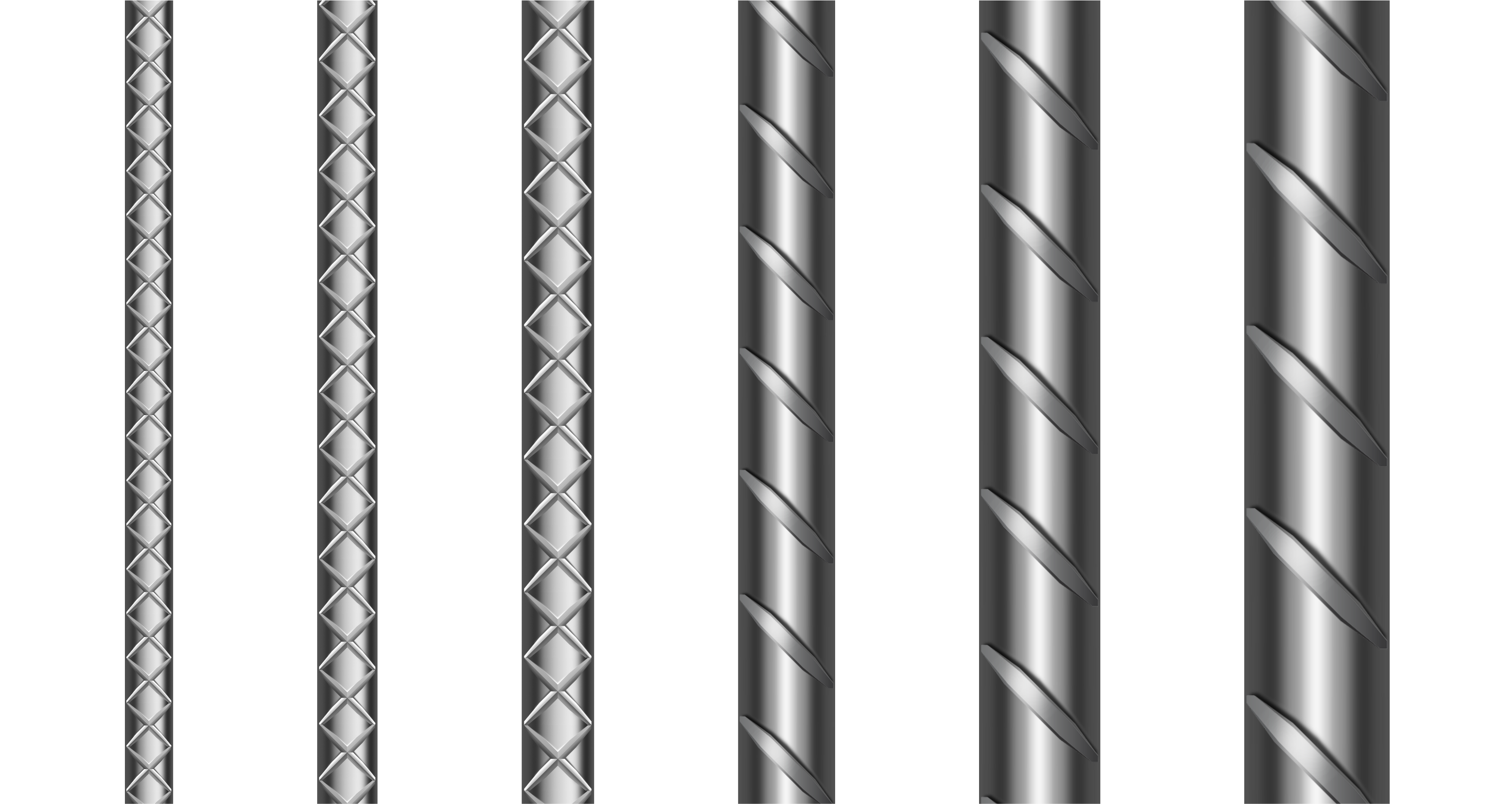

The grade of Steel is an important factor which governs the strength and durability of TMT bars. Moira TMT bars are high-quality bars using Fe-500, Fe-500 D, Fe-550, and Fe-550 D grades as per IS Code. Our bars are ranging from 8mm to 40mm diameter offering a wide variety as per the need and type to construction.

Moira Sariya is declared stronger than conventional steel bars which provide approximately 20% stronger concrete structures with the same amount of steel and this has made us customer’s preferred choice in Central India.

Moira TMT Sariya is frequently used in reinforced cement concrete because of high tensile strength, weldability, and ductility. Higher ductility makes bar capable of elongation to withstand high stress and fatigue for long periods. Higher bendability is also an added advantage for creating a seismic resistant structure.