Due to its unique manufacturing process, a TMT or a Thermo Mechanically Treated steel bar has many advantages over regular steel bars. The highly evolved manufacturing process imparts extra strength to the outer regions of the TMT bar while keeping the inner core ductile.

The benefits for RCC constructions are many – high strength, ductility, corrosion resistance, and cost reductions – to name a few.

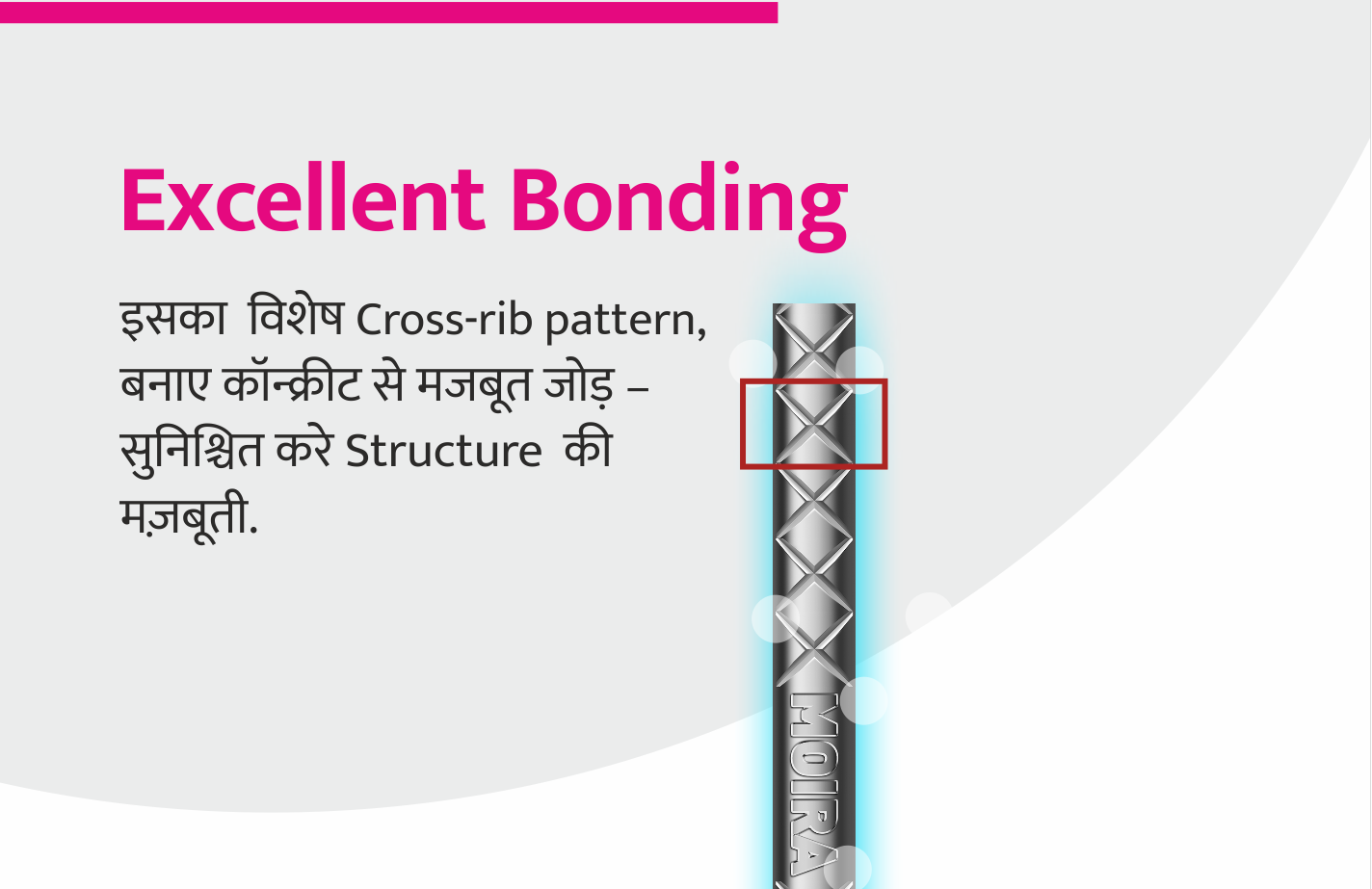

In this article, we discuss one of the unique features of TMT bars that contribute to its strength – its cross ribbed pattern.

What is the cross-ribbed pattern in a TMT bar?

Several well-manufactured TMT bars come with a pattern on its outer surface. At Moira Sariya, we make these patterns using CNC notch cutting machines, which ensure 100% uniform rib pattern on all TMT bars.

This ribbed pattern is essential for bonding with concrete. It provides anchorage to the concrete during the construction process and makes sure that the material has a good grip and doesn’t slip subsequently.

Why are cross-ribbed TMT bars better than plain TMT bars?

There are also plain TMT steel bars available for construction; these bars don’t have any ribs or deformations on its outer surface and are completely smooth. Here are some main features of plain steel bars –

- They have less friction

- They provide less bond strength between the concrete and steel components

- They are generally cheaper and consist of low carbon and silicon

- They are used primarily for re-melting, alloying and manufacturing of fabrication of steel structures. Usually, in construction areas where tensile strength is not a significant requirement.

Ribbed or Deformed TMT bars, on the other hand, offer at least 40% more bond strength due to its unique pattern. These deformations make it easy for concrete to grip the steel, which gives the structure more stability and durability.

- More friction and better grip ensure that slippage of material doesn’t occur.

- Especially useful in areas of RCC construction that requires high strengthreinforcement bars such as multi-storied building or bridges etc

- Extremely useful in the regions that are seismic prone as the bonding between the steel and concrete ensures structural integrity.

Conclusion

For all types of construction – especially for RCC construction of larger buildings and in earthquake-prone areas – cross-ribbed TMT steel bars are highly recommended by experts across the board. There is no doubt they make the structure more robust and increases its life. That said, while shopping around for TMT bars, you must check the credentials of the company and delve deeper into their specifications and manufacturing process because not all cross ribbed/deformed TMT bars are the same! At Moira Sariya, we only use using CNC notch cutting machines which ensure uniformity in the rib pattern, making the fatigue strength of Moira Sariya significantly superior to ordinary sariya.